Mold design and manufacturing is an important issue in the selection of mold materials, which directly affects a series of aspects such as mold service life, mold manufacturing process, mold processing cost, and molding quality of plastic parts.

In order to prolong the service life of the mold, a lot of research and engineering practice have been carried out on the surface strengthening treatment of the mold forming parts, and good results have been achieved. The working conditions of plastic molds are affected by both temperature and pressure.

Generally, the work is performed at 150~200 °C. The basic performance requirements of steel for plastic molding molds are roughly summarized as follows:

1. Sufficient surface hardness and wear resistance

The heat-treated mold should have sufficient surface hardness, and the hardness of the plastic mold is usually below 50~60 HRC to ensure that the mold has sufficient rigidity. The mold has to bear a lot of compressive stress and friction. Due to the filling and flow of plastic, this requires the stability of dimensional accuracy and the shape accuracy of the mold to ensure that the mold has a sufficient service life. Improving the hardness of the mold is conducive to improving its resistance. Abrasiveness.

2. Good machining performance

Steel grades that are easy to cut and can be processed to obtain high-precision parts should be selected. For this reason, medium carbon steel and medium carbon alloy steel are most commonly used, which is especially important for large molds. For parts that require EDM, this kind of steel is also required. The burn hardened layer of steel is thin.

3. Excellent polishing performance

High-quality plastic products require small cavity surface roughness. Therefore, the working surface of injection molded parts needs to be polished to a mirror surface. If the surface is too hard, polishing will be difficult. Therefore, the selected steel requires uniform and dense microstructure, less impurities, and no impurities. Fiber orientation, no pitting or orange peel defects when polished.

4. Good thermal stability

Plastic injection molds should try to choose materials with good thermal stability, because parts are often complex in shape and difficult to process after quenching. In order to ensure the dimensional accuracy and surface roughness of the mold, the deformation after heat treatment is small, and the dimensional change rate caused by temperature difference is small, so that the linear expansion coefficient of the molded part after heat treatment is small, the metallographic structure and mold size are stable, and processing can be reduced or stopped.

5. Good wear resistance and fatigue resistance

The injection mold cavity is not only scoured by the high-pressure plastic melt, but also affected by the temperature stress of alternating hot and cold. Generally, high carbon alloy steel can obtain high hardness after heat treatment, but its toughness is poor, and it is easy to form surface cracks, so it is not suitable for use. The selected steel grade should reduce the number of polishing and repairing of the injection mold, maintain the dimensional accuracy of the cavity for a long time, and achieve the service life of mass production.

6. Corrosion resistance

For some plastic varieties, such as PVC, flame-retardant plastics, etc., it is necessary to consider the selection of corrosion-resistant steel.

In addition, when selecting materials, it is necessary to prevent scratches and gluing, and if there is relative movement between the two surfaces, try to avoid selecting materials with the same tissue structure.

Main Features:

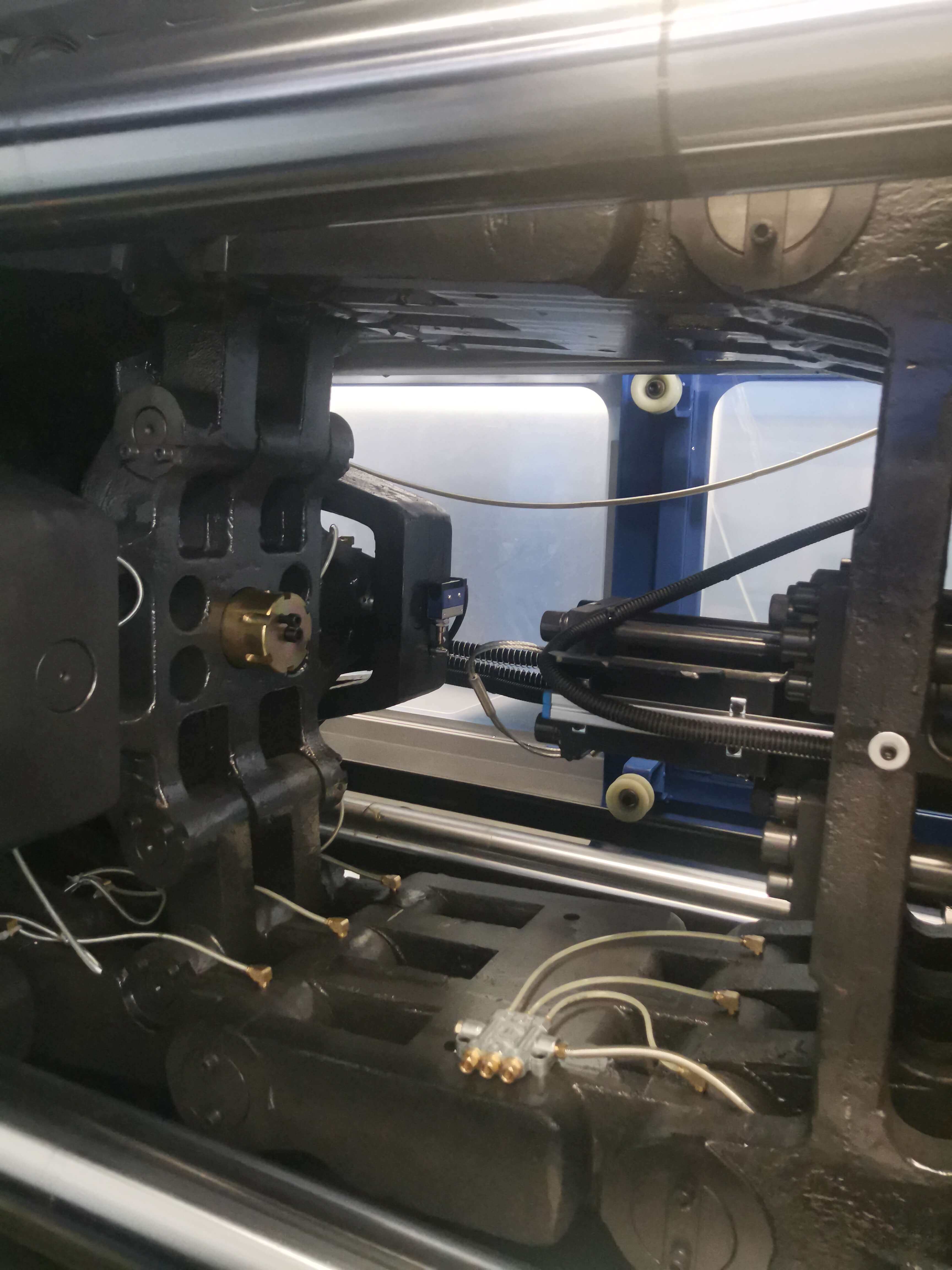

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.